Technisches Datenblatt

Mineralisch gebundene Wärme- und oder Trittschalldämmung für normale Belastungen.

Bezeichnungsschlüssel: BEPS-WD 70 R (RN) PREMIUM-PS(0-8)RN-LD60-FMD100-DMD70-MU6-CS(10/50)-CC(1,9/1,2/10)10-SD40

| Bezeichnung | Beschreibung | Wert |

|---|---|---|

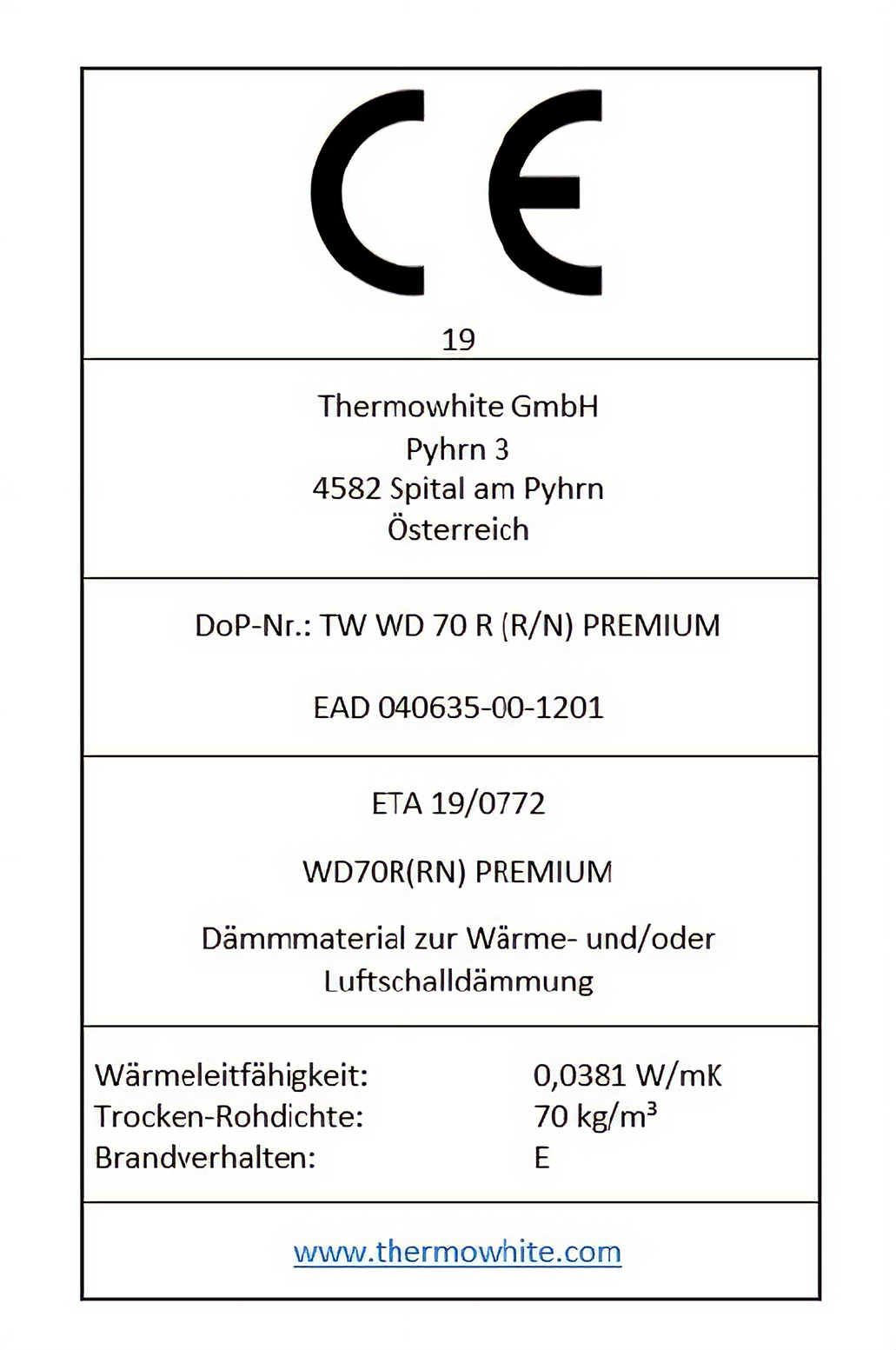

| 90%-Fraktilwert der Wärmeleitfähigkeit (trocken) | λ10 dry, 90/90 | 0,0381 W/mK |

| Bemessungswert der Wärmeleitfähigkeit | λR | 0,040 W/mK |

| Schüttdichte des EPS-Trockenmörtels | LD | 60 kg/m³ |

| Frischmörtel-Rohdichte | FMD | 100 kg/m³ |

| Trockenrohdichte | DMD | 70 kg/m³ |

| Druckspannung bei 10% Stauchung | CS (10)50 | > 50kPa |

| Wasserdampfdiffusionswiderstand | bei 6 cm | µ * d = 4,5 m |

| Brandverhalten nach EUROKLASSE*** | E | |

| Korngruppe des EPS-Zuschlagsstoffes | 70% 2 - 8 N (Graphite) / 30% 0 - 8 R | |

| Wasserbeigabe je m³ | 36 Liter | |

| mind. Einbaudicke**** | 35 mm | |

| Zusammendrückbarkeit bei Belastung (Diff. zwischen dL und dF) | mit 5 kPa (500 kg/m²) | 0,6 mm |

| Verarbeitungszeit (offene Zeit, 20°/60 % LF) | mind. 40 min | |

| Verarbeitungstemperatur min/max | +5° / +35°C | |

| begehbar ab | 24 Stunden* | |

| belegereif ab (CM-Messung) | ≤ 15 CM-% | |

| bei Einbaudicke bis 200 mm (23°C /50 % LF) | ca. 2 Tage** | |

| Ausgleichsfeuchtgehalt in Anlehnung an ÖNORM EN 12429 | 5,5 M% | |

| Trittschallminderung (gem. EN ISO 717-2) | 25 dB |

* Je nach Temperatur und Luftfeuchigkeit.

** Die Angaben sind als Richtwerte zu verstehen. Eine CM-Messung ist erforderlich.

*** Ein Wärmedämmstoff aus EPS kann im Brandfall das Ausbreiten von Feuer verhindern, er stellt allerdings keine Feuerbarriere dar.

**** Mindestdicke zur Erreichung der Trittschallwerte. Keine Mindestdicke für alle anderen Anwendungen.

Stand 06/2023 | ThermoWhite GmbH · Pyhrn 3 · 4582 Spital am Pyhrn · Austria

Zurück zur Startseite